System Components

RECEIVERS

SHUT-OFF VALVES

RECEIVERS

The Hartmann Receiver is uniquely designed to compensate for expansion due to fluid freezing and is the fill point for ground level fill. It is compatible only with the Hartmann DEF Nozzle. The non-standard interface prevents cross contamination with fuel, coolant, etc.

DEF Fast Fill Fluid Control System

DEF Fast Fill Control System

DEF Fast Fill Control System

DEF Fast Fill Control System

- Closed fill system prevents pressurizing DEF reservoirs

- DEF transfer closed system design eliminates external contamination

- The ability to connect and disconnect while supply line is pressurized

Standard Operating Procedure

DEF Fast Fill Control System

Standard Operating Procedure

- Energize supply pump

- Attach DEF Fill Nozzle to receiver

- Actuate Nozzle

- Shut-off valve opens and filling begins

- Displaced air escapes through vent

- Once the fluid level in the tank has reached the "full level", the fill level control signals the shut-off valve and nozzle to close

- No more DEF can be introduced into the reservoir

- Remove nozzle and the vehicle is ready for service

Key System Features

DEF Fast Fill Control System

Standard Operating Procedure

- Fill rates up to 800 LPM/200 GPM

- Positive shut-off prevents spillage and pressurizing of reservoir

- Fluid specific nozzle and receiver prevent cross contamination

- Remote vent prevents pressurization, allowing the use of think wall or molded reservoirs

- System tested to -40 degrees

- 100% DEF compatible materials and components

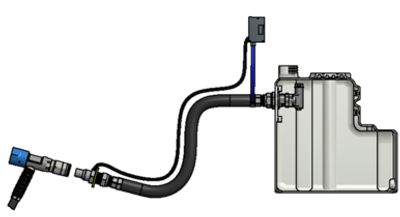

Hartmann Dri-Line™ Evacuation System

A self-contained fluid evacuation system for Tier IV Final engines using SCR to prevent fluid or DEF lines from freezing. Designed for off-road and heavy duty applications.

The Patent Granted Dri-Line™ Fill System was designed for fluid transfer applications where removing the fluid in a conduit is necessary due to freezing, reactivity, contamination, fluid value, or environmental safety concerns. The Dri-Line™ eliminates the need for costly drainage systems, heated hoses, heated couplings and receivers, and the power supplies, controllers, wiring, and other electronics to support these devices. The Dri-Line™ enables instantaneous filling upon startup. The Dri-Line™ system forces all fluid out of the conduit and into the reservoir, leaving only a trace of fluid that cannot impact future operations even if frozen. Evacuating the conduit typically recovers 99% of the fluid in the conduit and requires less than 1% of the energy needed in heated lines. The Dri-Line™ Ground Level Fill (GLF) was originally designed to deal with the complex issues of GLF of Diesel Exhaust Fluid (DEF) into construction and mining equipment.

KEY SYSTEM FEATURES

- Eliminates issues surrounding fluid line freezing

- Eliminates electrical energy required for heating hoses

- Provides instantaneous fill capability; no waiting for frozen fill systems to thaw

- Operates independent of on-vehicle CAN-BUS or other on-board control systems

Control Box

The control box consists of a pressure source, pressure relief switch, and controller. The box requires a 10 Amp circuit and has an optional battery pack that allows the system to operate for up to 40 hours after system power is disabled.

Copyright © 2020 Hartmann Controls DEF Delivery Systems - All Rights Reserved.

Powered by GoDaddy Website Builder